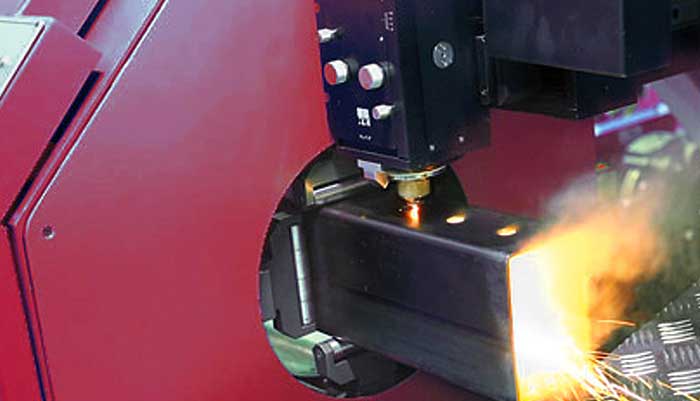

Cnc Laser Machine

The tube's inherent nature means that a laser generator is not required. While flat sheet laser cutting machines are now available with laser generators of up to 12 kW, tube-cutting machines typically require a maximum power of 5 kW. Tubes require you to be aware of the opposite side when cutting. A more powerful laser would cut through the tube's other side. (Officially, the tube laser can be used to process a beam or channel.

Medical device manufacturing is possible with precision and maximum uptime using Coherent Laser Systems for cutting, welding drilling, texturizing and marking.